A limited liability company incorporated under the company’s act No.17 of 1982 of the Democratic Socialist Republic of Sri Lanka, Technip Trailers Pvt Ltd counts three years’ experience import from CIMC china and disturb to local Market in Sri Lanka. The current clientele comprises of leading private sector and Government organizations in Sri Lanka.

“TECHNIP TRAILERS (PVT) LIMITED operating under dealership and main agent the CHINA CIMC company. CIMC is a huge market and good investments company in china. CIMC special vehicles co ltd is equipped with the manufacturing capacity of 5000 special vehicle s per year. CIMC with the top class production equipment’s in Asia. TECHNIP TRAILERS (PVT) LIMITED having its registered office and factory complex at No.71/D, Avissawella Road, Welivita, Kaduwela. Maintains an Island wide dealer and Sales Agent network.

01. Advanced technology: Major parts and components of the trailer are processed by advanced equipment’s. Longitudinal beams are fini – shed by automatic tracking submerged arc welding machine; all the sub – assemblies are shot – blasted to improve paint adhesiveness and are painted before assembling.

02. Chassis: To ensure optimal structure for cargo handling and larger payload, the chassis is manufactured as a space frame structure of high – strength steel, 16Mn steel welded longitudinal beam and integrated cross member.

03. Axle: High Performance domestic and imported axles with ABS system optionally available can significantly increase driving safety.

04. Suspension: High Strength and impact resistance new type suspension is adopted with patented rod connecting design. It guaran – tees performance in rough road condition and longer service life.

05. Tool Box: Large capacity water – proof detachable tool box.

06. Hot – rolled structural steel welded Mn steel longitudinal beam and cross member are assemble and welded for chassis assembly. The finished chassis offers bending and deforming resistance with proper rigidity and strength.

07. Tested and proven structure of cargo box is constructed with profiled steel frame, corrugated plate and mould pressed steel stake.

08. Reliable dual circuit air brake with quick release valve and quick response of wheel cylinder ensures safe on – road and off – road operation.

01. Main – frame: Longitudinal beam, using high structural steel and offering bending and shock resistance, can meet heavy load require – ment.

02. Sub – frame: using high strength 16Mn structural steel and integrated hydraulic system increases operation accuracy. Widened turning point of tipper body increases the overall stability, reliability and safety of the operation.

03. Body structure: Broadened high strength body stake and cargo body thickness can be tailored into different types according to needs for transportation of gravle, coal and other material. Self – lock and unlock system on the back plate ensure safe and reliable operation.

04. Tipping mechanism: Mallery type rear dumping, front tipping rear dumping, side dumping, side dumping mechanisms are available for customer order.

01. As to the single vehicle , we use second – class chassis of international and national famous automobiles to refit, such as Jiefang , Dongfeng , Hongyan , steyr , Auman , Northern Benz , Ghalefar etc.

02. The tank body is desugned by means of three – dimensional aid design method with the characteristics of reasonable structure, large effective capacity and reduced transportation cost.

03. We use OEM fitting, an international and national famous brand, shick make the tanker solid and dutable, and reduce the cost to operate and maintain.

04. The sub frame and walking mechanism in semi-trailer are made of high strength GB steel, and they are welded by a special welding machine, which can make the self – weight, and ensure its abilities of anti – seismic and anti – jolt, and meet different loading requirements on different roads.

05. The mixing blade is designed is designed by the latest Europe technique, which could realize the material to be mixed more evenly by three dimensions, and not easy to get centrifugal.

06. The liquid tanker is produced with the special equipment’s such as large special – purpose coiling plate machine and special welding machine which can realize welding by one side in shape by two sides, having the merits of stable quality, less coat, and good – looking.

07. The bulk powder goods semi – trailer has been awarded two national patents, it uses the latest fluidized structure with the characteristics of large capacity, low center of gravity, few remnants, simplified structure, quick discharging, etc, easy to operate and maintain

The yard trailer is designed and manufactured to transport 1×20”, 2×20,”1×45” ISO containers with customized specifications to suit different terminals. Rich experience for manufacturing special equipment for terminal service supplied many famous companies. The roller trailer is designed for use in stevedoring and transporting 1x40ft or 2x20ft and 1×45’ ISO containers or loose cargo or big non knocked- down goods on Ro-Ro vessels or within terminal areas.

conformed to miss operation prevent conception, streamlined easy to clean.

Full auto control system & automatic acceleration, rear ABS side cover, ejection plate retreats automatically when tailgate falling down, all operated by one button.

Auto – lock Hook, Chloroprene rubber seal with 3 layers, U – seal extended to top to prevent side leakage and back-flow and second pollution.

Over 10 safety devices applied, leading nationwide

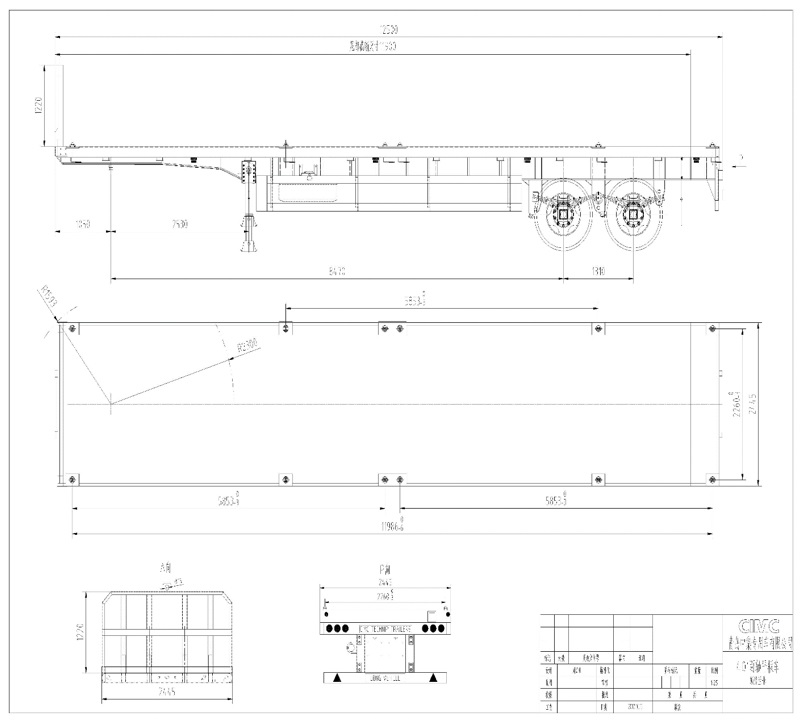

| Type | 40’ flat bed Semi-trailer with 2 axles |

| Model | 40 Foot 45Tone 2Axle Flat bed |

| Dimension (mm) | |

| Length×width×height | Length×width×height |

| King Pin Setting | 1050 mm from front edge |

| Axle Space | 8470mm+1310mm |

| Tare Weight | Approximate 5200Kg |

| Pay load | 45000Kg - 50000Kg |

| Main Beam | 500mm x 200mm,submerged arc welding Flange (T 14mm/B 16mm)and Web 8 mm |

| Extra reinforcemants | 24 No\s of extra reinforcemants for side raves & twist lock beams |

| Container lock | 12No's retractable ISO standerd container locks |

| Deck floor | 4mm checker plate |

| Shot blasting | SA 2.5 ISO standerd shot blasting & surface finishing |

| Paint | primer + top coat airless paint (Total DFT- 200µ) |

| Landing Gear | Fuwa 28ton dual speed gear operating landing legs Kingpin 2”JOST, exchangeable |

| Suspension | FUWA over slung mechanical suspension with10 leaf spring, 13mm*90mm |

| Axle | Brand new original FUWA 13T 2pcs |

| Tire | Ling long brand, type: 295/80R22.5,equip 10 per chassis |

| Wheel Rim | Type: 9.0 *22.5, equip 10 per chassis |

| Head board | Boltable 8' X4' fully covered head board |

| Brake System | Dual air brake system,30/30 type rear axle, WABCO brake valve with quick releasing switch with "C" coupler male & female |

| Electrical System | 24v LED light with 7-pin ISO socket |

| Others | 01) 02 No's of spre carriers with spaer wheels |

| 02) 08 No's of aditional winch wracherts | |

| 03) 24 No's of lashing hoocks | |

| 04) 08 Nos of piller post pockets | |

| 05) 04No's of plastic mud guards with mud flaps on last mud guard. | |

| 06) 1000mm X 500mm X 500mm heviduty,bolted, waterproof tool box | |

| 07) 02No's of number plate lamps for trailer & primover number plats | |

| 08) Spare wheel operating liver and 32mm- 36mm wheelbase | |

| Note | Lamps, stickers, indicators and all sings as RMV regulations in Sri Lanka. |